Bet On Black – King Engine Bearings pMax Racing Bearing System

09 Nov,2018

Engine bearings are one of those items, where because you don’t see them on a regular basis, they suffer from the “out of sight, out of mind” problem. The only time the average performance enthusiast thinks about their bearings is when first assembling the engine, and when there is a problem. Even when you do think about them, they generally are not visually appealing, flashy parts, so they don’t grab your attention.

King Engine Bearings has decided to come at that problem from both ends of the issue. Primarily, its line of pMax Black performance engine bearings are designed to allow you to forget about your bearings once the engine is built, thanks to much-increased longevity afforded by the construction of the pMax Black system. Also, thanks to the visual appearance of the pMax Black system, they add a bit of flash to the inside of the engine, which catches some attention during assembly. Not really a tangible benefit, but still cool in our eyes.

In addition to the pMax Black bearings themselves, King Racing has also developed a coating specifically for the pMax Black line of bearings which improves the lineup’s performance even further. Combined, the pMax Black and the pMax Kote coating make a set of engine and rod bearings which will perform at the hThe pMax Black and pMax Kote are two distinctly different items, which work together. The pMax Black is the specialized top layer of a tri-metal bearing. The pMax Kote is a coating, designed specifically for the pMax Black overlay, and is designed to further increase the bearing’s strength and durability.ighest levels of competition.

pMax Black – The Badass Bearing

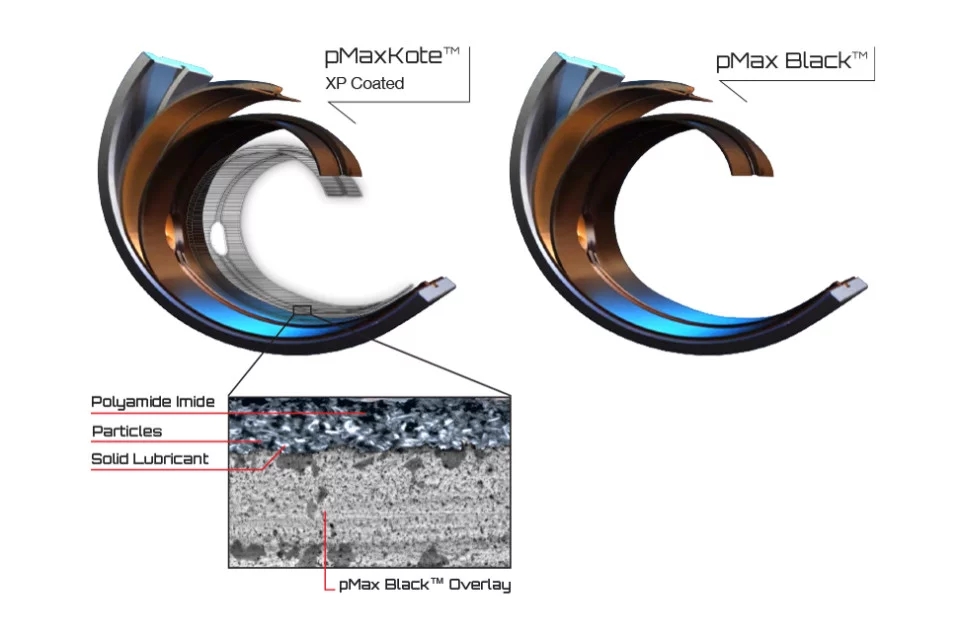

The main component in the pMax system is the pMax Black bearing. Available for both mains and rods, the pMax Black is a tri-metal construction bearing, but where it differs is the top metal layer, which is referred to by King as an “overlay.” Not to be confused with a coating, the overlay is a distinct layer of the bearing itself.

“The pMax Black overlay has a chemical hardening process that creates a fatigue resistant shield on the bearing surface,” explains Ron Sledge, King Engine Bearings’ Performance and Technical Manager. “The babbitt overlay is further strengthened by raising the copper content to 5-percent in the layer.”

King doesn’t only address the top of the overlay either, because if the layers were to ever separate, all the technology in the world would be worthless. “We use a Secure Bond micro-etching process, which improves multi-layer adhesion and structural integrity of the bearing as well,” Sledge says.

So between the surface hardening on the face of the top layer of the bearing, and the improved bonding between layers, the resulting bearing has an incredible load capacity. “The pMax Black bearing features a 10,200-psi load rating, which makes the overlay about 24-percent stronger than anything else on the market,” relates Sledge. Its purpose is to provide an anti-fatigue, wear-resistant layer to the bearing structure for long durations of very high loading.”

The pMax Black uncoated bearings – seen here in the Ford EcoBoost variant – owe its appearance to the specially treated top layer of the bearing stack. It’s chemically hardened surface provides an increased load rating and strength over standard bearings.

The technology incorporated into the pMax Black bearing is aimed directly at the race-only market, for several reasons. “The pMaxBlack bearings are recommended for all-out, constant high-load racing where the engine will be torn apart and inspected more frequently than passenger car engines,” Sledge says. “The very thin overlay provides additional fatigue strength as compared to thicker .001-inch overlay found in regular conventional tri-metal bearings.”

While the thickness – or thinness, rather – provides a fatigue advantage in a high-load setting, it is the reason that pMax Black bearings aren’t recommended for street engine use. “Street-driven engines that run at low-RPM and are lightly loaded, which aren’t rebuilt very often, need bearing materials that can embed foreign debris without damaging the bearing and crankshaft,” Sledge explains. “Due to the very thin .0005-inch overlay on the rod bearings, and .0007-inch-thick overlay on the mains, pMax Black isn’t recommended for street-driven vehicles.”

The pMax line of bearings, both “standard” pMax Black and the pMax Kote coated line, are available in rod bearings, as well as main bearings.

pMax Kote: An Additional Layer of Goodness

Unlike other coatings in the King lineup, the pMax Kote is only for use with the pMax Black bearings. “The pMax Kote is designed specifically to be applied on top of pMax Black overlay tri-metal bearings,” Sledge explains. The color of the bearing appears to be the same whether coated or not, so you have to pay attention to part numbers, as there is no visual indication of whether the bearing is coated or not.

“[pMax Kote] contains nano-sized wear-resistant particles, like ceramic and other solid lubricant materials in a polymer base. King applies the coating as part of the manufacturing process, not on top of a finished bearing,” Sledge says. With the pMax Kote an integral part of the bearing construction, it essentially becomes a fourth layer of the bearing, as opposed to a sacrificial coating.

“pMaxKote is designed to be a very wear resistant coating. We set out to formulate a coating that would provide the traditional benefits of a coating but at the same time make it very wear resistant,” says Sledge. “Not only did we achieve that, but we are able to apply it with no additional wall-thickness to the normal bearing wall. This provides better accuracy in determining oil clearances during the build process.”

The benefits of a coating which Sledge alluded to, are that during times when the oil pressure or volume isn’t sufficient in the engine, the coating can provide some additional lubricity. “Normally the bearing is separated from the crank journal by the oil film and two should never touch each other. The coating is in place as insurance to protect both parts from damage if the oil film breaks down or is lost,” Sledge says.

“The coating acts as a lubricant during times of super thin oil films, also known as oil starvation. It protects both the bearing and the crankshaft surfaces from damage due to contact between the two.”

Using top quality parts, such as pMax Black bearings, in your performance engine build – whether you are running a high-end four-, six-, or eight-cylinder engine – is like life insurance for the engine. The pMax Kote coating is an additional insurance rider on top of that, to help keep your performance engine alive in the case of a loss of oil pressure. The combination of both pMax Black bearings with pMax Kote applied is a superior combination that will allow your performance engine to reach the pinnacle of its performance envelope . A full list of available pMax Kote applications can be found here, with more applications being added all the time.

The pMax Kote polymer coating has been specifically designed for the pMax Black line of bearings, and provides exceptional wear resistance, even in the face of oil starvation, where there may be metal to metal contact.